Engineering

NVM offers our customers engineering expertise to assist with every aspect of organization’s requirements to create the most efficient and cost effective design. Our engineering services include prototype development, medium to high volume production needs and other value-added inputs. We offer design & engineering capabilities in Solid Works, 2D and 3D CAD/CAM, and AMADA’s CAD/CAM.

CNC PUNCH PROCESS:

- • Specialist in high speed production allowing several parts to be completed in a single setup.

- Press Capacity: 20 Ton Punching force

- Process 4’ x 10’ sheets with a single repositioning cycle

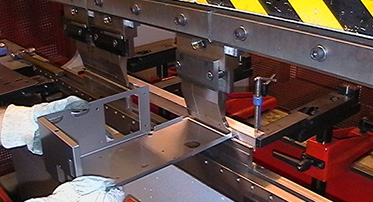

Amada CNC Press Brakes:

- Advanced design offers quick setup, high speed operation, and increased throughput.

- Allows staged bending with +/- ¼ degree angular accuracy.

- Press Capacity: 100 Ton with 8 feet bend length.

Automated Haeger Hardware Insertion:

- 6 Ton Ram force and 18 inch throat depth.

- Expertise in insertion of all types and sizes of self clinching fasteners.

Graining & Deburring

NVM utilizes state-of-the-art TimeSaver graining and deburring machine to provide our customers with scratch and burr free parts.

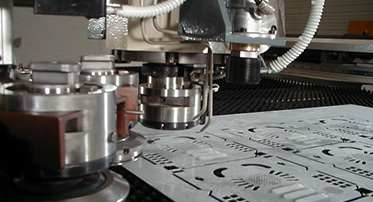

Laser Cutting:

NuVision Metals provides laser cutting for all your production needs from high-volume to short-run production requirements. Our engineers have the ability to take your CAD design files and seamlessly laser cut production parts with a high degree of accuracy.

Capabilities include:

- High Speed Piercing & mark free processing

- Urethane support disks which prevent marking on lower surface materials

- Fully Integrated CAD & PC-based touch control system

- High-Speed RPM to allow for quick product turnarounds

- Material thickness capacity:

- Steel: 1”

- Stainless Steel:0.250”

- Aluminum: 0.375”

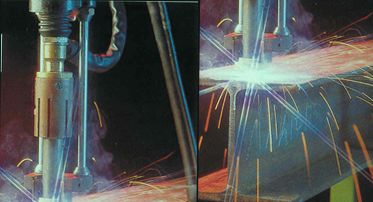

Stud Welding:

We offer Stud Welding also known as Arc welding to our clients in where we can weld hardware components, fasteners, etc. as part of the hardware integration & assembly processes. Stud welding is ideally suited for thin gauge materials due to the absence of reverse-side marking or discoloration. In addition stud welding eliminates the need for drilling, tapping, punching, riveting, gluing and screwing.

- Material Thickness 0 .010 - 0.187”

- Capacity 4-40 to 5-16

- Cold rolled steel

- Aluminum

- Satin coat steel (zinc-iron alloy)

- Stainless Steel

MIG/TIG Welding

NuVision Metals capabilities include both MIG and TIG Welding by our certified welders. We car capable of producing Class A welds on a wide variety of materials.

Materials:

We work with a variety of different material types from Cold Rolled Steel, Stainless Steels, Copper, Brass and Aluminum among many others. Our machines and equipment are capable of handling heavy gauge as well as light gauge materials, typical material thicknesses range from 0.010 – 0.187”.